Characteristics

SC decoilers are available in motorized and idle braked version, and may be in simple or double construction

CONSTRUCTION FEATURES:

| |

STRUCTURE

The electro-welded build structure is very strong, and ensures high preformances.

Thanks to the design and construction, it allows customers to add accessories also in a second time.

|

|

|

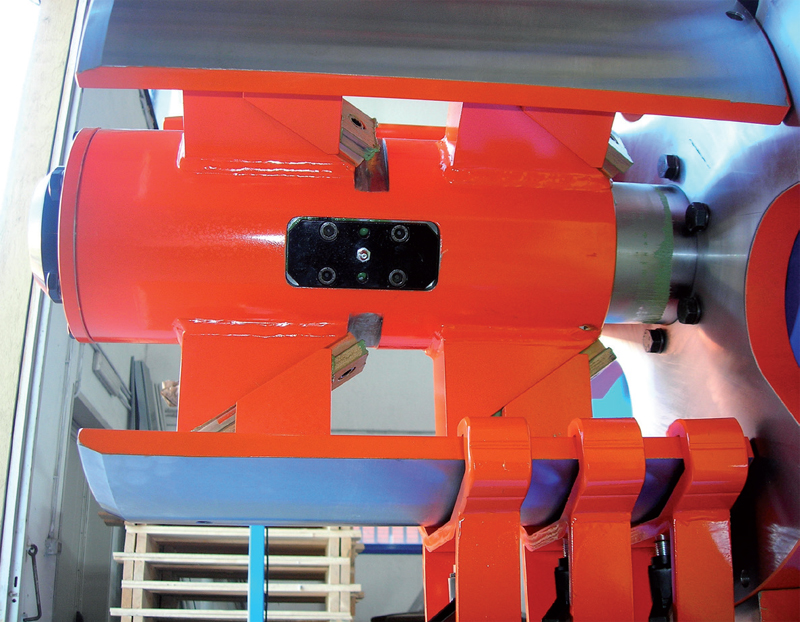

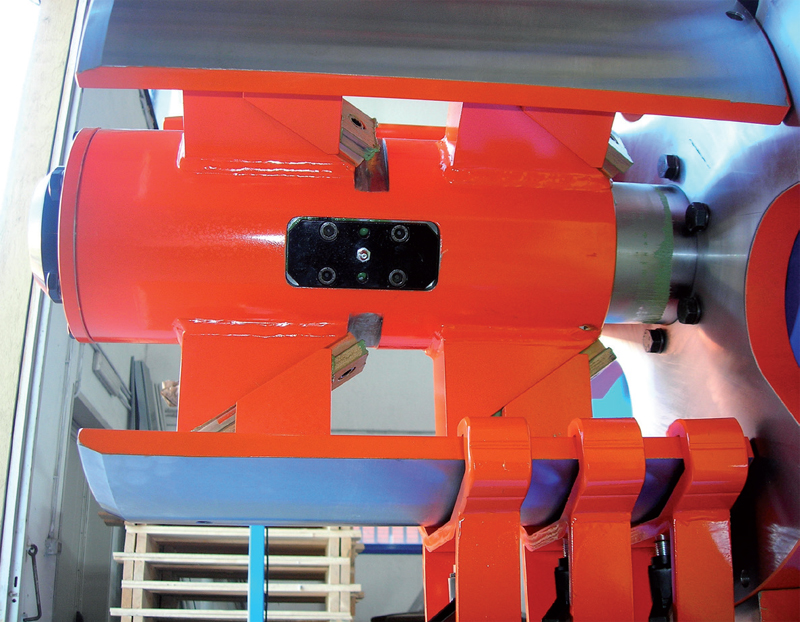

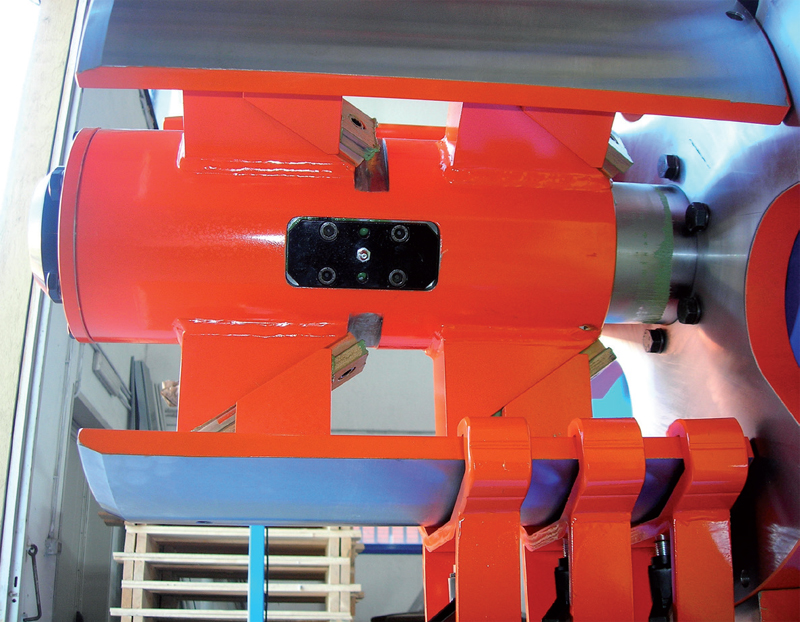

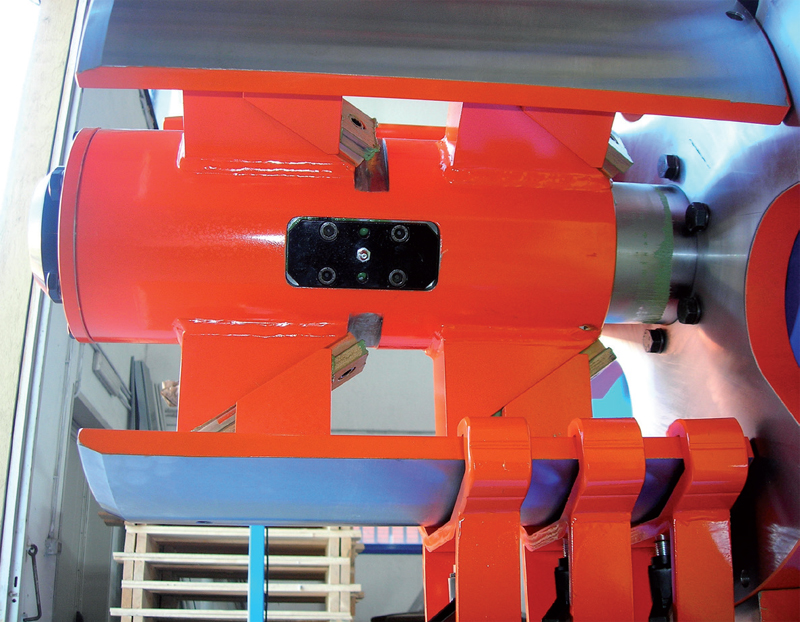

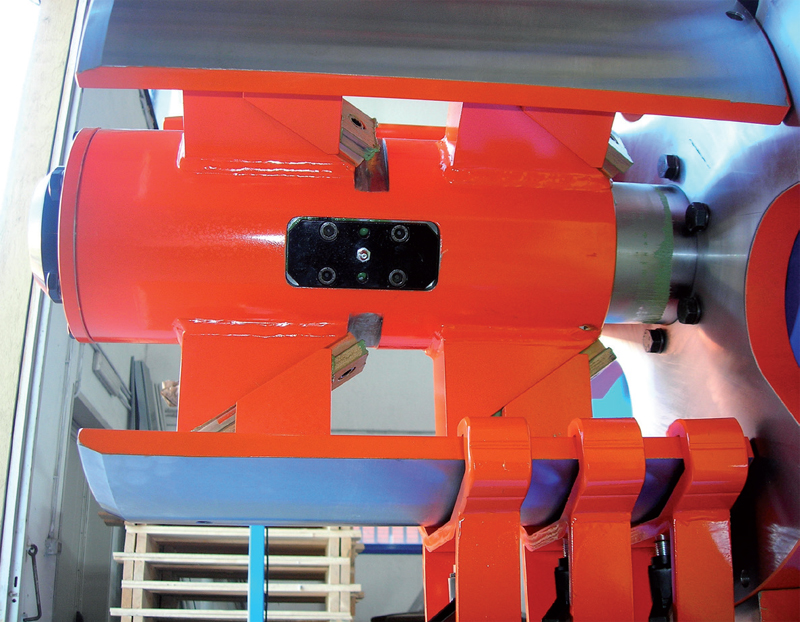

SPINDLE

The spindle is made of three curved and substantial sectors that are firstrly mounted onto the shaft and then shaped accurately on a lathe to obtain perfect concentricity with the shaft itself. This ensures both a perfect match to the inner spiral of the coil onto the sectors, and long machine life, as the weight is uniformly distributed onto the rolling bearings. Another important feature is that the section of the spindle is calculated with a safety coefficient equal to, or higher than 2.

|

|

|

LOOP CONTROL

There are different possibilities available :

|

|

Inductive sensor on the floor, detecting the presence of the strip. It stops the decoiler just before the strip touches the ground. As soon as the loop goes up again, the spindle restarts decoiling the strip. |

|

|

Feeler arm: it is in constant touch with the strip and its height determines the start or stop of the decoiling. |

|

|

Ultrasound or laser cell: the speed varies automatically according to the height of the loop. If the loop is too high and goes above the safety level, the line will stop. |

|

ACCESSORIES:

|

STIRRUPS

Stirrups prevent the strip from slipping down the sides during the decoiling; with narrow strips it is preferable to use the containing disks ( one frontside and one backside in tubular to be easy desassemblied) instead of the standard stirrups or to a fall arrest system with descent and lift up hydraulic movement and lateral translation by means of a crank handle to adjust the stirrups to the coil dimension.

|

|

|

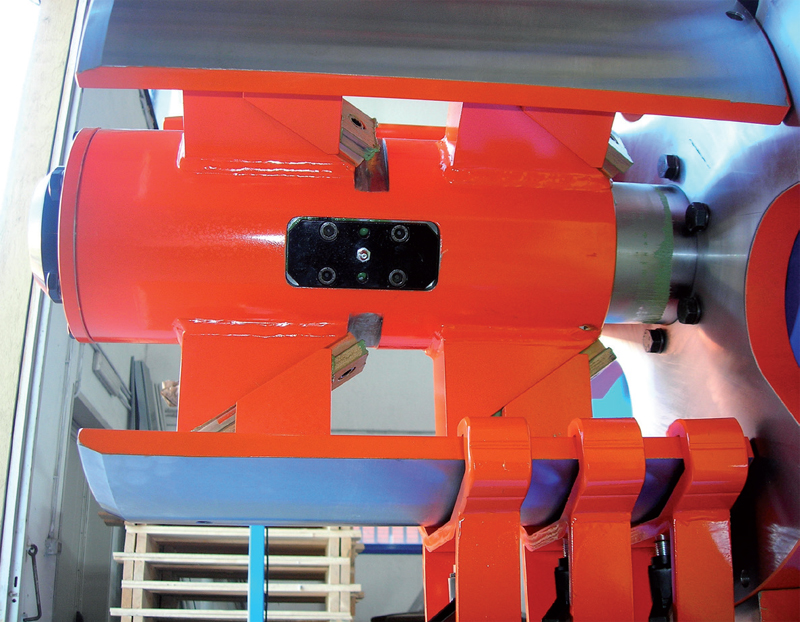

PRESSING ARM WITH BRAKED OR MOTORIZED WHEEL

May be either pneumatic or hydraulic. Its pressure on the strip helps keep the spirals of the coil well compacted, especially when the operator cuts off the safety bands, and the strip is conveyed into the following machine. The pressing arm can be equipped with a motorized wheel to push the strip towards the following machine. In some cases (especially with hard strips in wich the weight can obstaculate the progression to the straightener) the arm can be assemblied with a hydraulic motorized Vulkollan wheel.

|

|

|

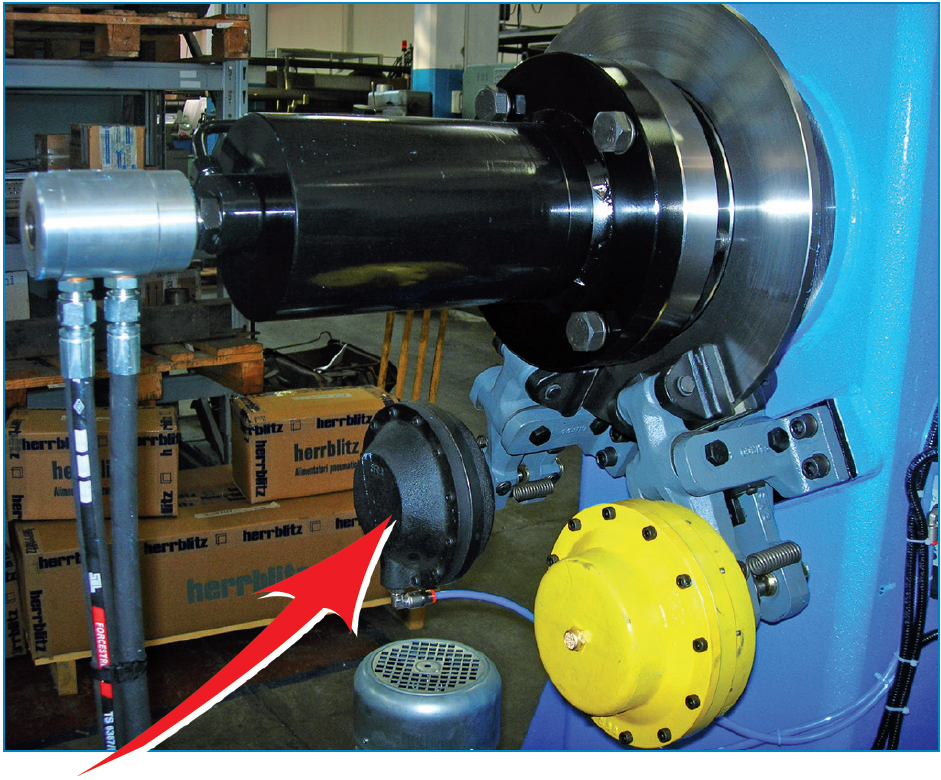

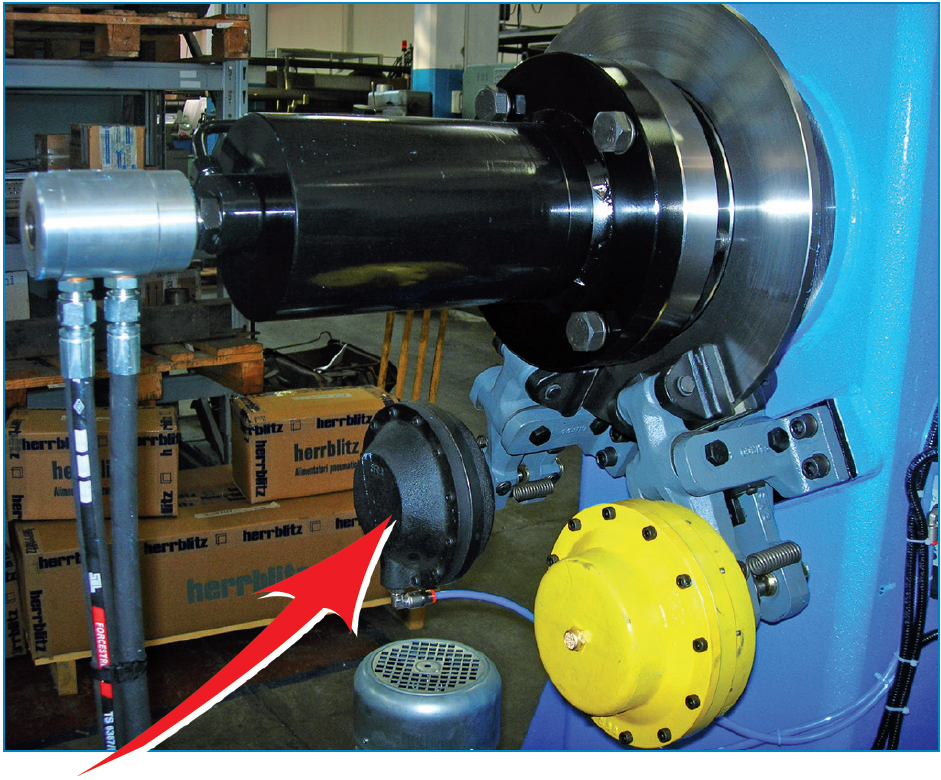

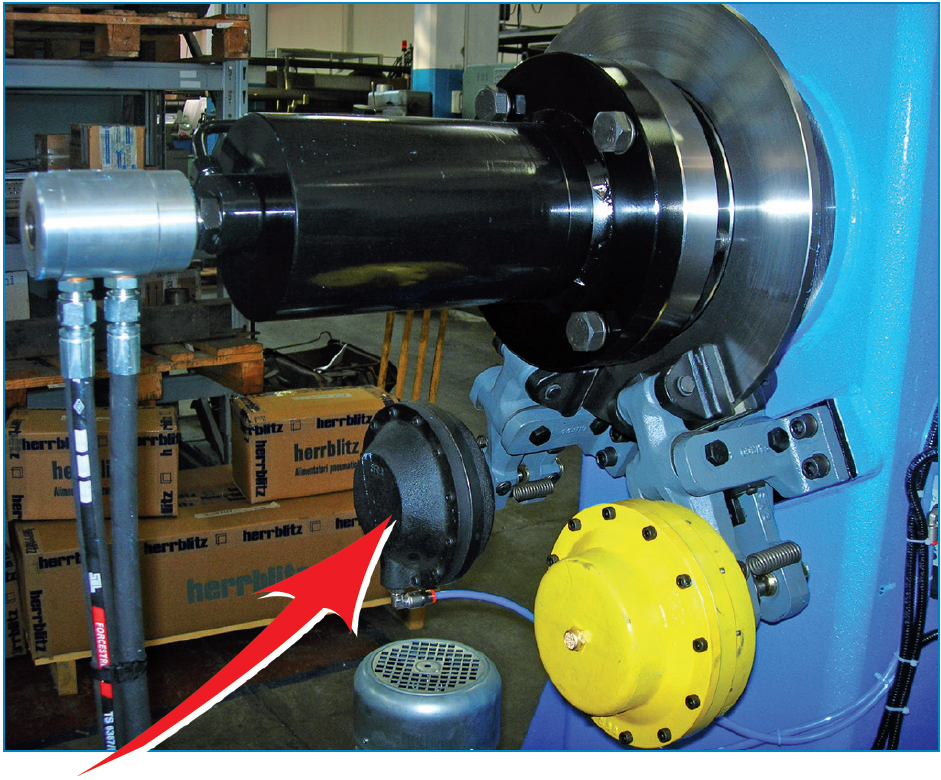

SAFETY BREAK IN CASE OF SUDDEN AIR LOSS

Safety breake stops any rotation of the spindle in case of sudden air loss or emergency situations, both on motorized and idle brake decoilers. This is particularly recommended for high speed running, and especially on idle decilers with pneumatic brake: it is activaded upon the unexpected loss of compressed air and a dangerous pressure drop; the safety brake becomes active straight away, this stopping any further decoiling.

It is suggested on idle decoilers with positive pneumatic brake and for motorized decoilers working on high speed.

|

|

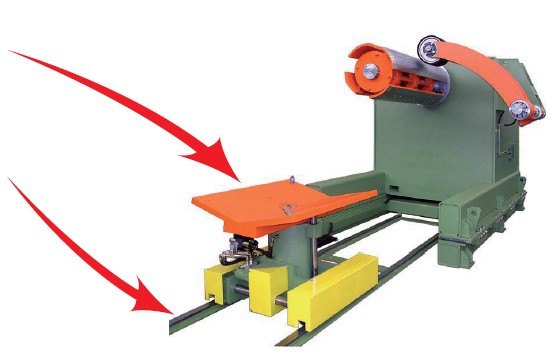

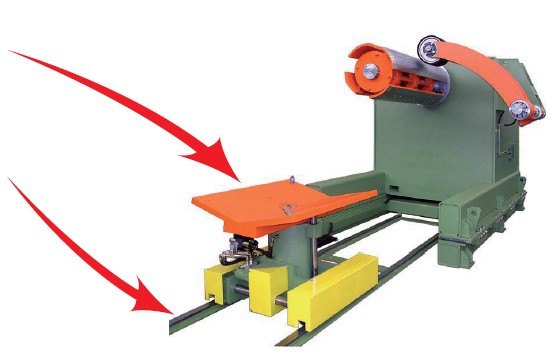

HYDRAULIC COIL LOADER AND RAILS

The coil loader is used for the automatic loading of the coil onto the decoiler's spindle, thnaks to its precise horizontal and vertical movement control. Available on different models dependinf of the weight. The tip over preventer is included. The coil loader moves on rails by means of hydraulic engine.

The rails may be fitteed on demand below the decoiler; they are used to move to the left or right to align the strip with the following machine.

|

|

ACCESSORIES FOR IDLE BRAKED DECOILERS

|

|

|

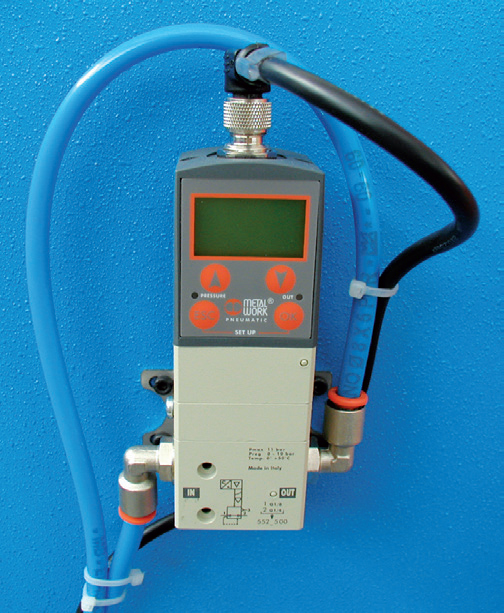

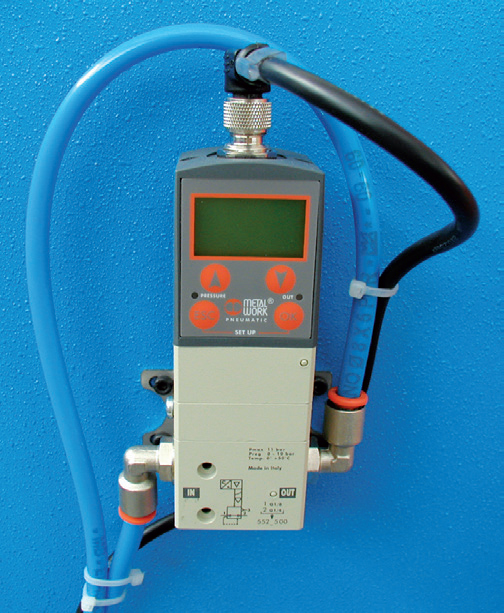

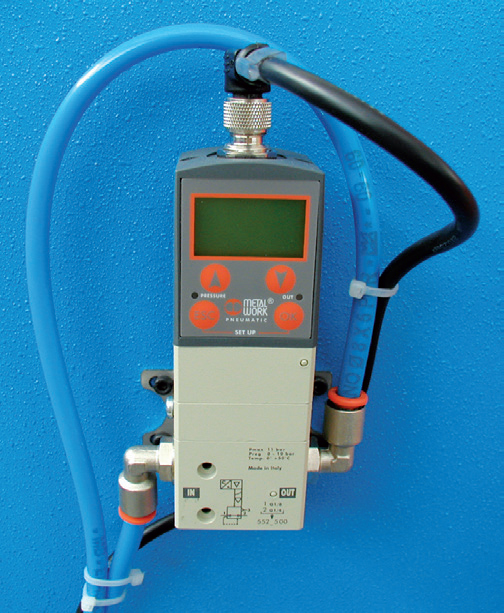

AUTOMATIC BRAKE ADJUSTMENT

On non-motorized decoilers, the decoiling is braked by the action of adisk brake with graphite pads: the braking force can be adjusted manually thanks to a handle.

On request a pneumatic brake with pressure reducer can be installed.

An additional option enables the operator to adjust the braking force by a proportional valve: an ultrasoundwill detect the external diameter of the coil, this determining the weight variation and consequently acting on the pneumatic proportional valve so that the braking force varies accordingly. It will brake mainly at the coil beginning due to the weight and it will reduce the brake action at the end of the coil.

|

|

|

|

|

|

HYDRAULIC MOTORIZATION

Used on idle decoilers to help the introduction of the strip into the following machine, or the recoling of the strip if needed.

|

|

|

|

© HERRBLITZ MODULAR SYSTEM SRL - Via Fossata 80/G 10155 Torino - Italy - P. IVA: IT06749780018 - Edited by Nahweb.net. All Rights Reserved.